TECHNOLOGY OVERVIEW

Ensyn’s patented RTP® technology is a commercial thermal conversion process that produces high yields of valuable biocrude from renewable cellulosic biomass, typically wood-derived feedstocks. Liquid biocrude yields are typically 70 to 75 wt% from dried wood residues. Byproduct combustible gas and char make up the balance and are used as an energy source to run the plant and dry the biomass feed material. Ensyn's RTP process is the leading technology, worldwide, for the commercial production of liquids from wood biomass using fast thermal conversion.

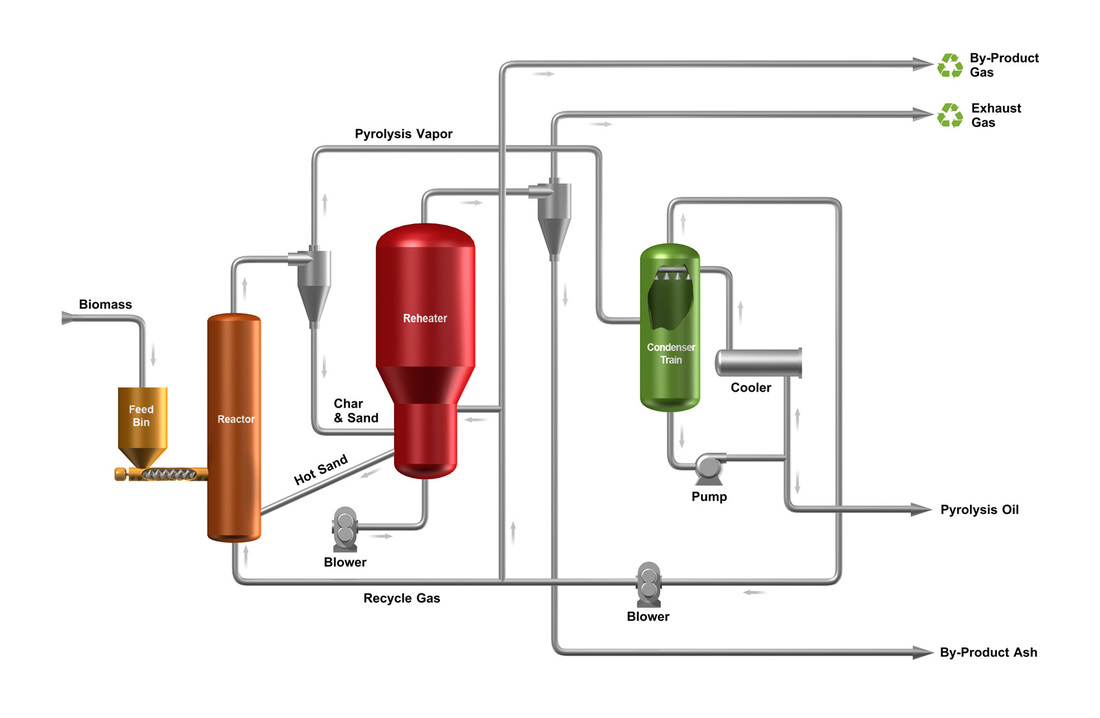

Ensyn has been applying its core RTP technology for more than 30 years for the production of food ingredients, chemicals and heating fuels. It has designed and commissioned 15 RTP facilities for various applications and feedstocks, at different scales, and six RTP facilities are currently in commercial operation. Ensyn is now in the process of increasing production capacity to meet the increasing demand for its liquid fuels. RTP is an elegantly simple process The Ensyn RTP process is based on the rapid thorough contact of hot flowing sand with biomass, which quickly fragments the solid feedstock into vapors, gases and char. The vapors are rapidly quenched, or cooled, and recovered as a free-flowing light biocrude, while the gases and char flow together to a second vessel where the sand is reheated and recirculated back to the conversion unit. Heat is recovered from the gas and char, and used to supply heat for various RTP process applications. The by-product gas is used as a fuel for complementary applications such as biomass drying, or electrical power generation, while the char is typically consumed in its entirety in the reheater to provide the heat required to drive the process. Excess thermal energy, in the form of flue gas, is available for biomass drying or may be directed to a heat recovery unit such as a steam generator. The conversion of biomass to biocrude occurs in less than two seconds. The RTP process does not require expensive complex catalyst systems, hydrogen, or high pressure. These factors, coupled with very short processing time, translate to attractive capital and operating costs. Over twenty-five years of commercial operation and process development has led to processing equipment that is simple, robust and reliable. RTP represents a close analogue to equipment used in refineries worldwide The RTP process is similar to Fluid Catalytic Cracking, or FCC, a common and mature process used by the old industry in most refineries to convert petroleum feedstocks to gasoline, diesel and other products. FCC systems circulate catalyst in a closed loop between two key vessels, a conversion unit and a catalyst regenerator, while transforming petroleum into transportation fuels and petrochemicals. Ensyn uses a similar mechanical process, but circulates an inert sand heat carrier, instead of catalyst, to convert wood residues to high yields of a free-flowing liquid biocrude. Ensyn's RTP is protected by a robust patent portfolio Ensyn’s RTP technology is supported by a portfolio of patents on a variety of significant aspects of the process. Ensyn’s patent strategy aligns with Ensyn’s business focus on continuous development. As innovations and improvements emerge, new patents are filed. Ensyn’s current patent portfolio consists of 41 patents granted and 5 pending patent applications in the U.S., as well as 163 patents granted and 44 pending patent applications outside of the U.S. Technology Alliance with Honeywell UOP Ensyn's extensive experience with the RTP technology is now complemented by a broad technology alliance with Honeywell UOP, a global leader in developing and commercializing technology for the oil refining, petrochemical, gas processing and hydrogen industries. This alliance includes licensing and supply of RTP equipment (carried out through Envergent Technologies) and commercialization of Refinery Co-Processing. Feedstocks Ensyn’s RTP efficiently converts a wide range of “woody” biomass feedstocks to valuable liquid fuels and chemicals. These can include:

|

RTP Introduction

Simplified RTP Process Flow

Click to enlarge

Envergent Technologies, a joint venture between Honeywell UOP and Ensyn, provides RTP licensing, engineering & equipment supply to biocrude production projects worldwide, with performance guarantees.

Honeywell UOP is subcontracted by Envergent Technologies to carry out RTP design and engineering for biocrude production projects. In addition, Honeywell UOP and Ensyn have established an alliance to commercialize Refinery Co-processing.

|

Technology Overview

ABOUT |

PRODUCTS |

© COPYRIGHT 2015. ALL RIGHTS RESERVED.